Beeketal

Beeketal Poultry Plucking Machine Wet Plucking Machine - BRM2050

Item number 953

Variantennummer:BRM2050

Technical data:

| Model: | BRM2050 |

| Connection: | 230 V - 50 Hz |

| Power: | 1500 watts |

| Absorption capacity (pcs./passage): | 2 - 8 |

| Quantity (pcs./hour): | approx. 250 |

| Pass duration: | approx. 1 minute |

| Drum diameter: | approx. 630 mm |

| Total load: | max. 10 kg |

| Load for single animals: | max. 7 kg |

| Dimension (L/W/H): | approx. 700 x 700 x 970 mm |

| Picking fingers: | 209 |

| Power cable length: | approx. 1200 mm |

| Net weight: | approx. 68,5 kg |

SHIPPING INFORMATION:

Please provide your valid email address as well as phone number when ordering, as the item will be shipped by freight forwarding company.

Shipping by freight forwarding takes about 3-7 days.

Recommended by a master butcher with 20 years of slaughtering experience!

Recommended by a master butcher with 20 years of slaughtering experience!

NOW NEW: Unit on rollers, thus easy to transport!

New model with integrated spring ejection

New model with integrated spring ejection Improved design

Improved design

On rollers, 2 rollers with brakes

On rollers, 2 rollers with brakes

Suitable for chickens, ducks, light geese, chicken

Suitable for chickens, ducks, light geese, chicken

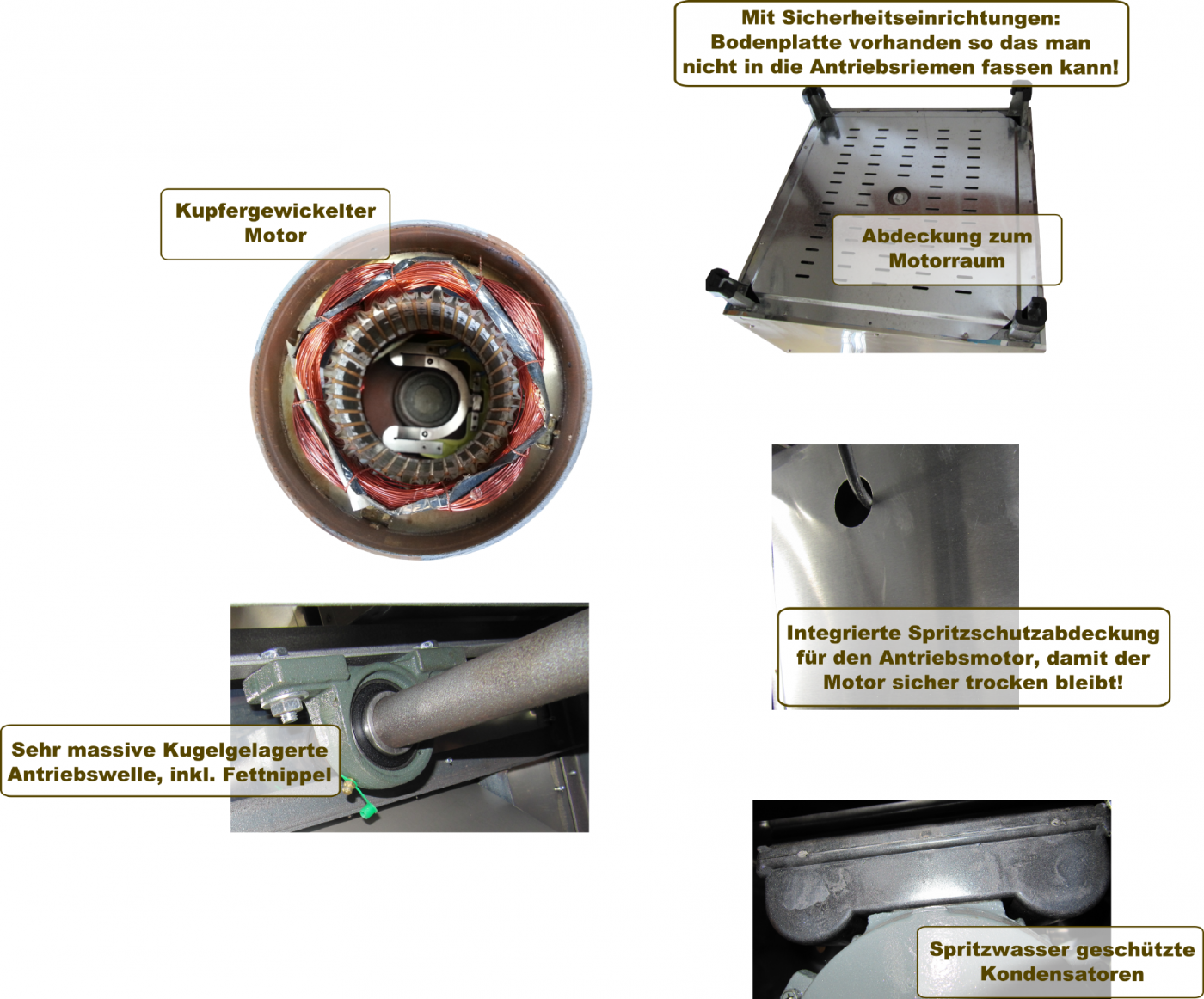

Copper wound motor

Copper wound motor

Ideal for agriculture, hobby farmer, small business without EU approval etc etc.

Ideal for agriculture, hobby farmer, small business without EU approval etc etc.

Unfortunately, this model is not suitable for wildfowl.

Unfortunately, this model is not suitable for wildfowl.

================================================================================

Dear Customer / Interested Party

Please read this paragraph carefully BEFORE making a purchase decision:

Some offers from other suppliers advertise payloads of over 13 kg or more than 4 birds at a time per plucking pass. One should see it realistically, since as known a chicken has a fattening period of only 30 to 40 days. Excluded are heavy fattening animals with significantly higher slaughter weight.

These animals have a lot of meat but also a very soft bone structure in relation to the amount of meat.

Therefore, it can lead to bone fractures on wings as well as thighs when more than one slaughter animal is loaded.

In this case, the meat is no longer in its original shape and is covered with bone splinters. Furthermore, with a load of 4-5 animals, the skin on the thighs can be torn by the claws of the animals and the thigh can thus be torn, even fold away. Then the carcass is no longer compact and very unsightly. If the skin was opened/destroyed at such mentioned places, strong germ infestation is the consequence by contamination of feathers, excrement and scalding water.

In my time as an active master butcher, it was always decisive in the meat processing industry and in smaller companies to achieve the highest yield. If you then have to dispose of wings or thighs due to incorrect slaughter because they are no longer edible, you should approach the slaughter realistically.

Logically, the cleanest defect-free slaughter is always only one slaughter animal per pass through the plucking machine. Therefore, my advice to you: please do not be swayed by utopian numbers and throughputs that subsequently result in defective carcasses.

Please also consider the sizes/dimensions of the machine before buying one that is too small. Large geese and turkeys need a certain amount of space to be able to rotate realistically in the machine and plucking of all feathers without slaughter damage is given.

The number of plucking fingers is not decisive, but the arrangement of the plucking fingers!

Likewise an additional FI switch at the equipment is not compellingly necessary, since each household/business must have secured the current supply over an FI circuit breaker. With some machines offered in the Internet the cover must be opened to the FI switch, in order to be able to switch these on or off. If you touch the open switch with wet hands, which is the case during the slaughtering process, water can run past the switch into the housing.

We have an on/off switch on our poultry plucking machines, which are certainly moisture-proof.

No water can penetrate. Furthermore, our motor is copper wound and splash-proof: also from the bottom side.

The motor and the capacitors are additionally again provided with a housing and prevents a splash water infestation.

In addition, accidental tampering with the drive belt is impossible, as we have installed a base plate on our machines that prevents this. This is impossible with the BRM series from Beeketal, as we pay great attention to work safety and quality and are constantly improving the machines, also through ideas and feedback from our customers.

==================================================================================

BEEKETAL POULTRY PLUCKING MACHINE:

You have a lot of poultry to pluck? Plucking by hand is too time consuming and exhausting? The Beeketal poultry plucking machine BRM2050 offers you high performance and that at an affordable price.

No matter where you want to use the Beeketal plucking machine, the poultry plucking machine enables you to efficient and easy work.

Due to a very good quality of workmanship, special plucking fingers and the construction with integrated rinsing ensures that the poultry plucking machine really only plucks the feathers. Injuries to the poultry are thus largely avoided and a high quality is achieved when plucking the poultry.

The Beeketal poultry plucking machine impresses with its simple robust technologywhich performs its work almost indestructibly. The simple and safe handling is particularly noteworthy.

It is recommended to process only one poultry at a time. Of course, it is also possible to pluck several poultry at the same time. However, there is a risk that the poultry will tear each other's skin with their claws.

Therefore we recommend to process only one poultry at a time to achieve a perfect plucking result.

The ejection chute of the poultry plucking machine is positioned at a suitable angle to ensure that the feathers do not slip.

The poultry plucking machine is affordable and due to the high possible throughput, the profitability is second to none. So your investment will probably pay off sooner than you think.

Hand on heart... The plucking of e.g. a duck is very time consuming. In the plucking machine the whole process takes only about 1 minute.

Information about the obligation to take back packaging material

According to the current packaging law, we are obliged to take back the following packaging materials according to § 15 Abs. 1 S. 1 VerpackG,

to take back the following packaging materials from end users free of charge:

-

Transport packaging, such as pallets, large packaging, etc.,

-

Sales and outer packaging that does not typically accumulate as waste at private end consumers after use,

-

sales and secondary packaging for which system participation is not possible due to system incompatibility pursuant to Section 7 (5), and

-

sales packaging containing hazardous substances, or

-

reusable packaging

Appropriate packaging material is used for the delivery of the product, which we take back free of charge.

We thus ensure that the packaging material is returned to the recycling cycle. By informing our customers about

the return options, we aim to achieve better results in the recycling of packaging and to contribute

to the fulfillment of the European recycling targets according to the EU Directive 94/62/EC.

You can return the packaging material as an end user at the place of actual delivery or in its immediate vicinity.